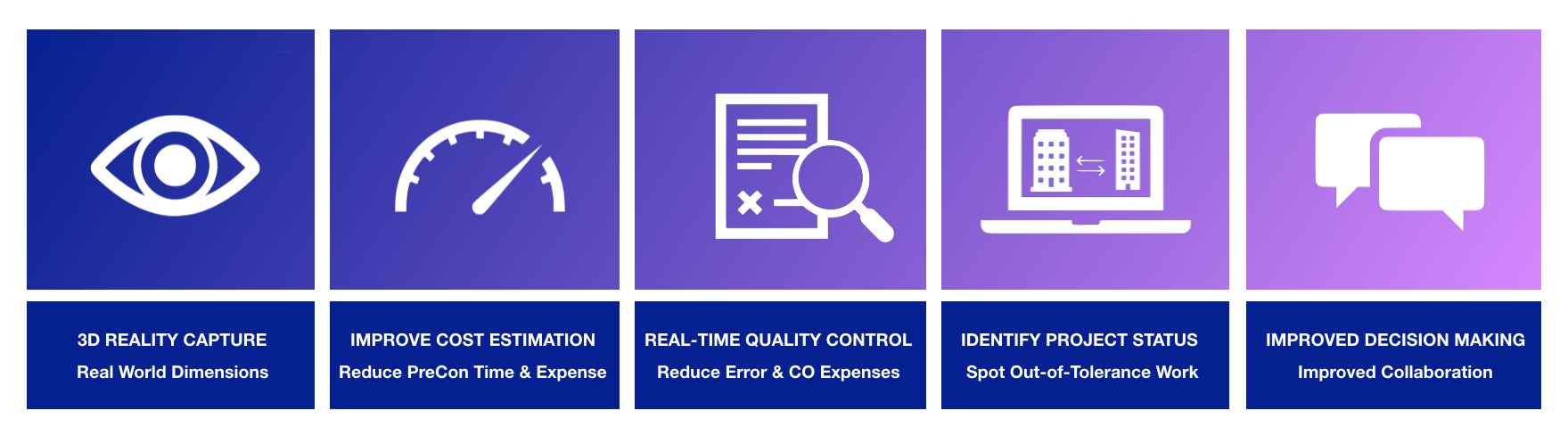

LASER SCANNING ADVANTAGES

We CAPTURE > PROCESS > ANALYZE > DELIVER

Protects Stakeholder’s Investment

Keeps Stakeholders Informed

Improves Decision Making

Builds Trust & Transparency

Improves Pricing Accuracy

Helps To Minimize Surprises & Cost Over Runs

Saves Money By Reducing Project Schedule Delays

Visuals Improve Comprehension

Improves Collaboration

Provides Mega Data At A Glance

A Tool That Makes The Estimating Process Better

A Sales Tool — Helps You Win More Business

Improves Quality Of Information

Reduces RFIs And PCOs

Minimizes Amnesia

Helps Manage Expectations

As-Built Architectural Models for Planning & Renovation

Scan Industrial, Warehouse, & Office Spaces for Retrofit Planning

Archival Documentation for Heritage & Preservation

Maps Out Structure, Rebar, Piping And Conduit For Future Changes

Enhance Weekly OAC Meetings With Current Progress & Problems

Keeps Everyone ‘In-The-Loop’ — From Any Location

Easily Compare Actual Build To BIM Models

Archives Historic Data

As-Built Verification For Remodel Planning

Real-Time Construction Quality Management

Validate Slab FF and FL Numbers

Construction Quality Assurance

“Clash Detection” Discovery

Discover ”Out-of-Tolerance” Work

Compare ‘Plans-To-Actual As-Built’ Conditions — Side-by-Side

Deliverables Customized For Downstream Applications

Scan It — When It Has To Be Right And You Can’t Afford To Be Wrong

Don’t Start A Project That’s Not Accurate

NEXT GENERATION > above Total Station

GAIN THE COMPETIVE EDGE

SAVE TIME & MONEY

ADANCED 3D LASER SCANNING

Deliverables Customized To Meet Your Needs

Why should I Invest in 3D Laser Scanning?

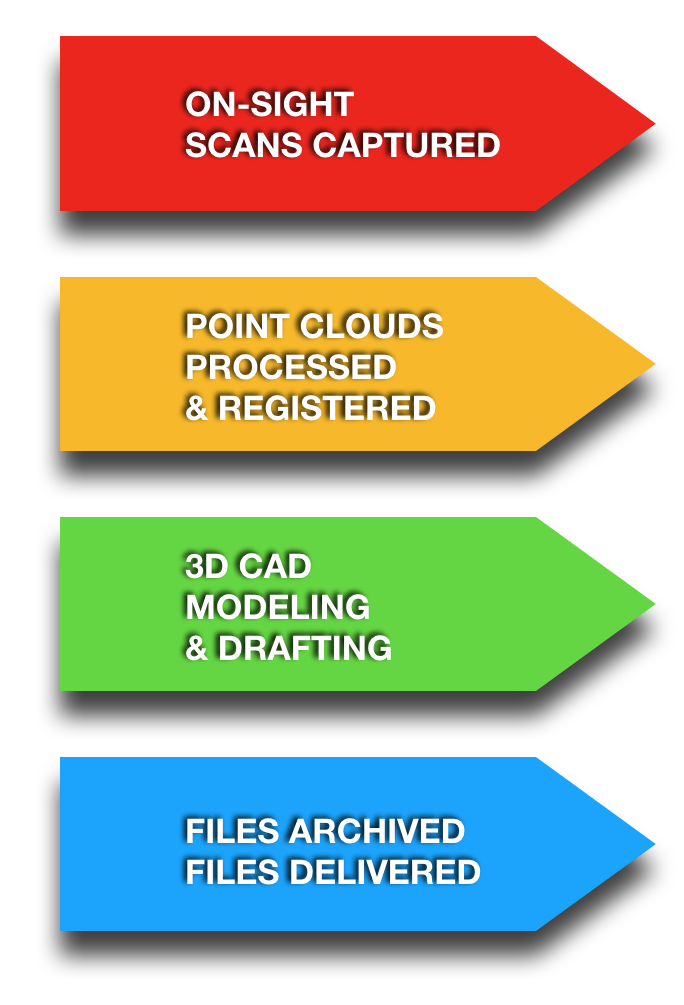

THE PROCESS

Why Scan

• FAST — AGILE — PRECISE

• Reduce Errors & PCOs

• Save Time & Money

• Real-Time Quality Control

• Verify As-Built Field Data

• Minimize Error Cost Impact

• Improved Decision Making

• FAST — AGILE — PRECISE

• Reduce Errors & PCOs

• Save Time & Money

• Real-Time Quality Control

• Verify As-Built Field Data

• Minimize Error Cost Impact

• Improved Decision Making

How We Do It

• We Define Your Needs

• We Capture Your Scans On Job Site

• We Register & Store All Captured Data

• We Model Point Clouds & Deliver Files

• We Respond To Your Special Requests

• We Develop Custom Modeling Packages

• We Define Your Needs

• We Capture Your Scans On Job Site

• We Register & Store All Data

• We Model Point Clouds & Deliver Files

• We Respond To Your Special Requests

• We Develop Custom Modeling Packages

The Concerns

ARE 3D SCANNERS SAFE?

Yes… Our on-site laser scanning processes uses eye-safe instruments for most cases. For flammable environments, we use an explosion-proof scanner. 3D scanning promotes safety because it permits you to take measurements from a safe distance from you plant hazards.

HOW ACCURATE ARE 3D SCANNERS?

Depending on the type of scanning, accuracy can range from 1/8″ for building construction scanning and .0005″ for industrial ct scanning. The typical accuracy for an average small part is about .005″. The real question is “How Accurate Do You Need It?”

IS THERE A SIZE LIMIT?

Yes, but there is a very broad range: from about the size of a kernel of corn to bridges, dams, 20 story buildings, and large industrial facilities. For example, a mile-long oil refinery would be no problem. We have different types of scanners and software options to address the needs of a wide variety of projects.

How It Works

3D Laser Scans have the ability to document basically any structure to validate and record its actual “As-Built” existing condition, with extreme accuracy. In construction, for example, when architects and engineers need to capture the real world existing condition and measurements of buildings, roads & bridges, oil & gas plants, wind turbines, and industrial facilities, they have them scanned.

Each individual laser scan captures tens of millions of points in space. When combined, these points are referred to as a ‘Point Cloud’. A series of scans are taken, from strategic locations around the target. This ensures that the over-lapping point clouds completely capture and define the target in 3D space.

These point clouds are then ‘stitched’ together by a special software ‘registration’ program to form a three-dimensional image of the target. The complete ‘registered’ point cloud is then provided to the client for further processing on their computers.

In construction, for example, when architects and engineers need to capture the existing condition of a structure they just call Meyer3D. We scan buildings, roads & bridges, oil & gas plants, wind turbines, and industrial facilities. These highly detailed and accurate scans record and prove existing conditions. The client doesn’t have to send a team to the job site, climb ladders or even pull-a-tape. They can save hundreds of man hours and tens of thousands of dollars when they use our point clouds to capture the details of a project.

Sometimes our customers require additional processing and refinement of the point cloud data. Meyer3D also offers additional ‘CAD Modeling’ services that can convert our registered point clouds into a wide variety of deliverables in almost any format.

We even have software that can preform ‘clash’ and deviation checks that compare the actual structural build to the current blueprint requirements. This software can verify structural alignment and check to ensure that all the structural members were installed at their correct locations. It’s important to know that none of your required bracing was overlooked.

At Meyer3D, we only use the latest in scanning hardware, coupled with a full suite of software toolsets to provide the deliverables you need. From registered ‘Point Clouds’ for your team to use with their software, to refined 3D CAD-to-BIM modeling, Meyer3D will provide the information you need.

3D SCANNING SERVICES EXPLAINED

Laser Scanning Basics 101

UNDERSTANDING THE COST

OF 3D SCANNING SERVICES

BREAKING DOWN PRICE FACTORS FOR 3D SCANNING SERVICES

If you find yourself in the position of having to shop around for 3D scanning services, we understand that it can be a daunting task. Company A charges $300 to scan a small object, and Company B might charge $1000 to scan the same thing. If you are new to 3D scanning, this can be especially confusing.

Why does this happen?

1. COMPANY SIZE

Large companies that have been doing scanning for a while tend to have substantial overhead, with some “swag” built into their pricing. You can very easily end up paying double what you should with these large established companies. At the other end of the spectrum, there are always new businesses trying to break into the industry. They tend to charge low ball prices. Some independent contractors, like us, have very low overhead.

Meyer3D is a small Tulsa based independent 3D Scanning Consultant Firm. We provide timely local personalized service. We have the ability to balance our hourly rate pricing with client volume, payment history, current workload, and future scheduled commitments.

2. ESTIMATION VARIABILITY

Often, 3D scanning companies must estimate 3D scanning and 3D modeling time based on photos (and not always the best quality photos). This requires the estimator to make a judgement call based on prior experience. Some scanning projects are so unique that any estimate is merely an educated guess as to the time required to complete the project. It is easy to see in these cases how the cost of 3D scanning can vary between vendors.

If you are a regular M3D customer, requiring consistent deliverable requirements, our production time is decreased with each iterative assignment. We get to know you and merge ourselves into your workflows as we develop a better understanding of your needs. Over time, our production modeling times decrease substantially. Since we bill ‘by-the-hour’ our receptive clients typically see their project costs decrease over time.

3. APPLES TO ORANGES COMPARISONS

Sometimes companies will quote different types of deliverables. If you are not specific enough with the required output format in your initial quote request, one company may quote a less sophisticated output type at a much lower cost, giving the impression that they are cheaper when in fact they are not delivering the same type of result.

Of course the type of deliverable is the primary cost determining factor. A quick scan with a registered point cloud is our least expensive scanning option. It takes much less time than some of the full point cloud modeling requirements needed by some of our clients.

4. SPECIALIZATION

There are many types of 3D scanners, and every scanner has certain strengths and weaknesses. For example, some scanners may make scanning a 20 story building an easy task, where with other scanners it would be difficult, if not impossible. There are similar differences in software capabilities between scanning companies. Companies with an equipment or software advantage will be in a position to bid lower.

At Meyer3D, if you are a potential ‘long term’ high volume client, we will acquire the equipment and software to meet your specific needs. Production time is decreased, all work is done in-house. Everyone wins.

5. LOCATION

Obviously, a company that has a location advantage will not have to include travel in their costs and can be more competitive in their local area. Meyer3D specializes in work in and around Tulsa and OKC.

THE BOTTOM LINE: RESEARCH COMPANIES

The best advice we have for customers is to do your research on each company. Sometimes, it’s a risk going to the cheapest bidder. You don’t want a company willing to take shortcuts on quality. You may end up with poor quality or unusable product. A higher bidder might ensure better quality, but if the same quality work can be obtained for less, then you’re paying too much for your project.

There’s a lot of freedom in 3D scanning and 3D printing, but finding the company that best fits the unique goals for your project can be tricky. We are proud to be reliably less expensive than the bigger 3D technology companies (often by a factor of 2), yet not sacrifice quality.

Just remember, Meyer3D is a hometown company. We have a reputation to earn and protect. Your repeat business is our goal. Our pricing is both fair and competitive.

Compromise Elsewhere… Save Everywhere

SITE MAP

Meyer3D, LLC

10764 S. 93rd East Ave.

Tulsa, Oklahoma 74133

(918) 899-1932

All Rights Reserved © Meyer3D 2019

OKLAHOMA TITLE 245 LEGAL NOTICE: Meyer3D, LLC preforms support work for firms that are licensed under title Oklahoma Title 245.

Meyer3D, LLC DOES NOT claim to be a licensed Professional Engineer or a licensed Land Surveyor company and it is NOT licensed under OK Title 245 as such.

Meyer3D, LLC

10764 S. 93rd East Ave.

Tulsa, Oklahoma 74133

(918) 899-1932

All Rights Reserved © Meyer3D 2019